Full Name :

Styrene Butadiene Rubber

Description :

Polyamide 6, Nylon 6, or polycaprolactam (PA6) is one of the major engineering thermoplastics. PA6 is tough, has excellent abrasion resistance, good chemical resistance, fatigue endurance, lubricity, impact strength, high strength, and rigidity.

Key Properties :

Full Name :

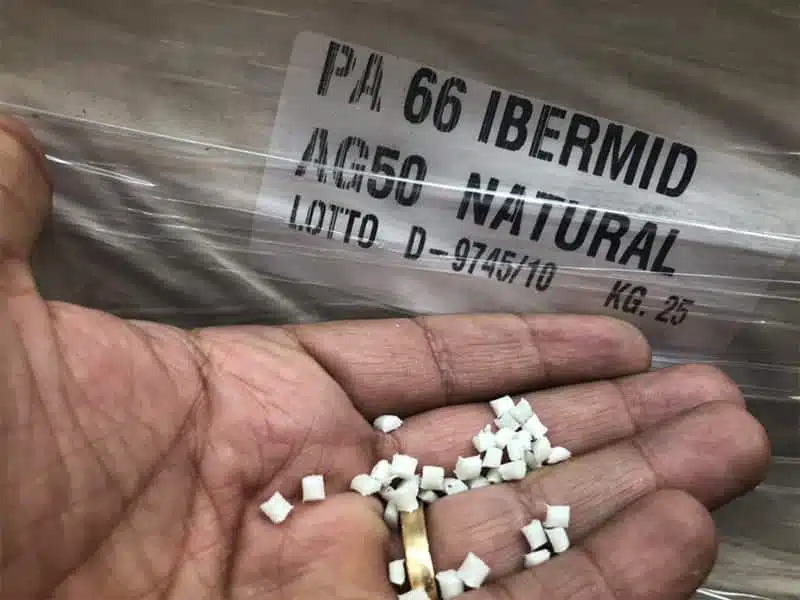

Polyamide66 / Nylon66

Description :

Poly (hexamethylene adipamide), Polyamide 66, or Nylon 66 (PA66) is an engineering-grade thermoplastic. PA66 has higher strength but lower impact resistance than PA6.

Key Properties :

Full Name :

Polyamide6+Glass Fiber / Nylon6+Glass Fiber

Description :

It is the same Polyamide6 / Nylon6 ,but it is so much more strength, from glass fiber

Key Properties :

Full Name :

Polyamide66+Glass Fiber / Nylon66+Glass Fiber

Description :

It is the same Polyamide66 / Nylon66 ,but it is so much more strength, from glass fiber

Key Properties :

Full Name :

Polymethyl Methacrylate / Acrylic

Description :

Polymethyl methacrylate (PMMA) has excellent chemical and weather resistance.

Key Properties :

Full Name :

Polyacetel

Description :

Polyacetal or Polyoxymethylene is a semi-crystalline engineering thermoplastic widely used to produce high precision parts thanks to high lubricity.

Key Properties :

Full Name :

Polycarbonate

Description :

Polycarbonate is a thermoplastic material that offers manufacturers and designers opportunities for design freedom, aesthetics enhancements and cost reductions. PC is known for maintaining coloring and strength over the time.

Key Properties :

Full Name :

Thermoplastic Elastomer

Description :

Thermoplastic elastomers (TPEs) are one of the most versatile plastics in today’s market bridging between the service properties of elastomers and the processing properties of thermoplastics. The cost effectiveness and design flexibility enable TPEs to be used in many major end-user markets, including consumer products, electronics, medical devices, automotive, and much more. Explore this comprehensive guide and learn everything you need to know about TPEs.

Key Properties :

Full Name :

Thermoplastic Rubber

Description :

TPR material is a material that has properties of both plastic and rubber. It is lightweight and has good abrasion resistance, good tear strength, weather resistance, and electrical properties. TPR performs similarly to vulcanized rubber and is reusable and recyclable. This material is also well suited for injection molding processing.

Key Properties :

Full Name :

Thermoplastic Urethane

Description :

Thermoplastic elastomer with high durability and flexibility. Understand how it is produced, its main properties and benefits which enable various industries to produce advance products. Also, get detailed information on popular applications of thermoplastics polyurethanes ranging from automotive to agriculture and many more.

Key Properties :

Full Name :

Acrylonitrile Styrene Acrylate

Description :

Acrylic-styrene-acrylonitrile copolymer (ASA) is a thermoplastic elastomer. This type of copolymer has excellent resistance to UV irradiation, heat, moisture, and stress cracking and probably has the best weathering resistance of all acrylonitrile elastomers. It also has good chemical resistance, and high impact strength. Its mechanical properties are very similar to acrylonitrile butadiene styrene (ABS) elastomers. However, unlike butadiene-based rubber, ASA has no double bonds in the polymer backbone, which results in significantly improved weathering and UV resistance as well as better long-term heat and chemical resistance when compared to diene rubbers.

Key Properties :

Full Name :

Polybutylene Terephthalate

Description :

Polybutylene Terephthalate (PBT) has high strength and rigidity for a wide range of applications. PBT is one of the toughest engineering thermoplastics.

Key Properties :

Full Name :

Polybutylene Terephthalate + Glass Fiber

Description :

Polybutylene Terephthalate (PBT) is a white or off-white semi-crystalline polyester similar in both properties and composition to polyethyleneterephthalate (PET). When compared to PET, it has somewhat lower stiffness and strength, is slightly softer but has very similar chemical resistance and higher impact strength. As it crystallizes more quickly than PET, it is usually favoured for industrial scale moulding.

Key Properties :

Full Name :

Ethylene Vinyl Acetate

Description :

EVA (ethylene vinyl acetate) is the copolymer of ethylene and vinyl acetate. It’s an extremely elastic material that can be processed like other thermoplastics. The material has low-temperature toughness, stress-crack and UV radiation resistance. EVA is widely used in the orthotic and prosthetic market for soft inner liners, inner boots.

Key Properties :

TECHNIC INDUSTRY COMPANY LIMITED

RUBBER & PLASTIC MANUFACTURER SINCE 1977.

38 Soi Ekkachai 55 Ekkachai Rd. Khongbangbon Bangbon Bangkok 10150 Thailand

© 2022 Technic Industry Co., Ltd. - All Rights Reserved.

CONTACT US