Engineering Plastic

PA6

Full Name :

Styrene Butadiene Rubber

Description :

Polyamide 6, Nylon 6, or polycaprolactam (PA6) is one of the major engineering thermoplastics. PA6 is tough, has excellent abrasion resistance, good chemical resistance, fatigue endurance, lubricity, impact strength, high strength, and rigidity.

Key Properties :

- High stiffness and strength at elevated temperatures

- Toughness at low temperatures

- Excellent heat aging resistance

- Very good abrasion and wear resistance

- Chemical resistance

- Excellent surface appearance, especially in filled and reinforced versions

- Excellent weld strength after vibration welding

General Plastic

PVC

Full Name :

Polyvinyl chloride

Description :

Polyvinyl Chloride (PVC or Vinyl) is a high strength thermoplastic material widely used in applications, such as pipes, medical devices, wire and cable insulation...the list is endless. It is the world's third-most widely produced synthetic plastic polymer. So, what is PVC? What is it made up of? How to process it? Get detailed technical information on Polyvinyl Chloride and its features.

Key Properties :

- Low cost, flexible & high impact strength

- Good resistance to UV, Acids

- Good electrical insulation properties

- Non-flammable & versatile performance profile

- Easier to process than rigid PVC

Rubber

SBR

Full Name :

Styrene Butadiene Rubber

Description :

Styrene butadiene rubber (SBR) is one of the cheaper synthetic general purpose elastomers that is sometimes used as a substitute for natural rubber (NR). It can be produced by free-radical solution polymerization or by emulsion polymerization either warm at 30 to 60°C (hot rubber) or cold at temperatures near 0°C (cold rubber). Emulsion SBR (ESBR) continues to lose ground to solution SBR (SSBR) which is better suited for high-performance tires. Nevertheless, emulsion SBR grades still account for more than 75% of the total world capacity as of 2015. However, more and more SBR is produced by solution polymerization.

Key Properties :

- Excellent abrasion resistance

- Excellent crack endurance

- Excellent water resistance

Silicone Rubber (VQM)

GENERAL PURPOSE

Full Name :

General Purpose Silicone

Description :

A silicone or polysiloxane is a polymer made up of siloxane They are typically colorless oils or rubber-like substances. Silicones are used in sealants, adhesives, lubricants, medicine, cooking utensils, thermal insulation, and electrical insulation. Some common forms include silicone oil, silicone grease, silicone rubber, silicone resin, and silicone caulk.

Key Properties :

- Low thermal conductivity.

- Low chemical reactivity.

- Low toxicity.

- The ability to repel water and form watertight seals.

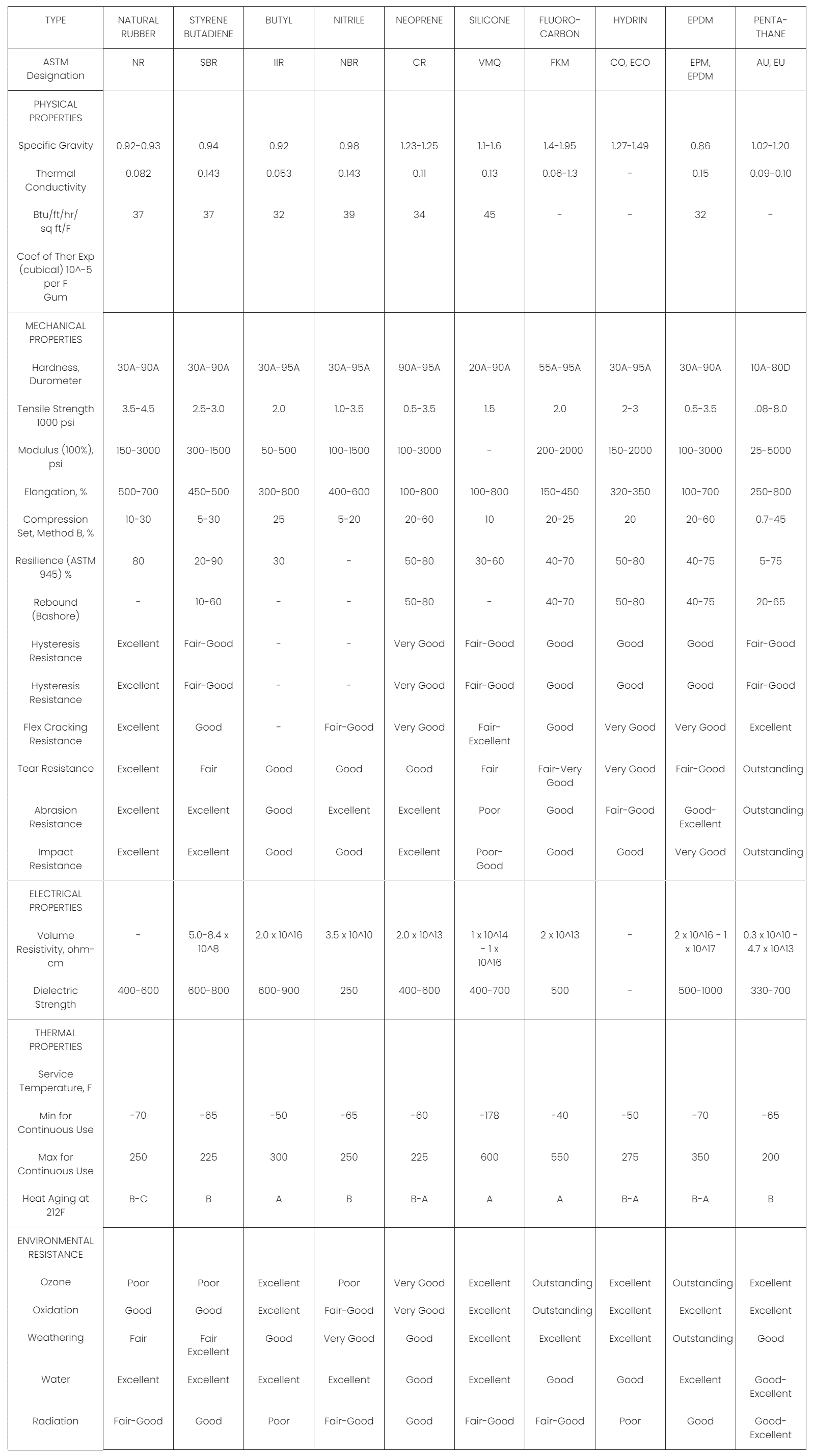

Guideline

TYPE

ASTM Designation

PHYSICAL PROPERTIES

Specific Gravity

Thermal Conductivity

Btu/ft/hr/

sq ft/F

Coef of Ther Exp (cubical) 10^-5 per F

Gum

MECHANICAL PROPERTIES

Hardness, Durometer

Tensile Strength 1000 psi

Modulus (100%), psi

Elongation, %

Compression Set, Method B, %

Resilience (ASTM 945) %

Rebound (Bashore)

Hysteresis Resistance

Hysteresis Resistance

Flex Cracking Resistance

Tear Resistance

Abrasion Resistance

Impact Resistance

ELECTRICAL PROPERTIES

Volume Resistivity, ohm-cm

Dielectric Strength

THERMAL PROPERTIES

Service Temperature, F

Min for Continuous Use

Max for Continuous Use

Heat Aging at 212F

ENVIRONMENTAL RESISTANCE

Ozone

Oxidation

Weathering

-

Water

-

Radiation

NATURAL RUBBER

STYRENE BUTADIENE

BUTYL

NITRILE

NEOPRENE

SILICONE

FLUORO-CARBON

HYDRIN

EPDM

PENTA-THANE

NR

SBR

IIR

NBR

CR

VMQ

FKM

CO, ECO

EPM,

EPDM

AU, EU

PHYSICAL PROPERTIES

0.92-0.93

0.94

0.92

0.98

1.23-1.25

1.1-1.6

1.4-1.95

1.27-1.49

0.86

1.02-1.20

0.082

0.143

0.053

0.143

0.11

0.13

0.06-1.3

-

-

0.15

0.09-0.10

37

-

37

32

39

34

45

-

-

32

-

Coef of Ther Exp (cubical) 10^-5 per F

MECHAN

PROPER

30A-90A

-

30A-90A

30A-95A

30A-95A

90A-95A

20A-90A

55A-95A

30A-95A

30A-90A

10A-80D

3.5-4.5

-

2.5-3.0

2.0

1.0-3.5

0.5-3.5

1.5

2.0

2-3

0.5-3.5

.08-8.0

150-3000

-

300-1500

50-500

100-1500

100-3000

-

200-2000

150-2000

100-3000

25-5000

500-700

450-500

300-800

400-600

100-800

100-800

150-450

320-350

100-700

250-800

10-30

-

5-30

25

5-20

20-60

10

20-25

20

20-60

0.7-45

80

-

20-90

30

-

50-80

30-60

40-70

50-80

40-75

5-75

-

-

10-60

-

-

50-80

-

40-70

50-80

40-75

20-65

Excellent

-

Fair-Good

-

-

Very Good

Fair-Good

Good

Good

Good

Fair-Good

Excellent

-

Fair-Good

-

-

Very Good

Fair-Good

Good

Good

Good

Fair-Good

Excellent

Good

-

Fair-Good

Very Good

Fair-Excellent

Good

Very Good

Very Good

Excellent

Excellent

Fair

Good

Good

Good

Fair

Fair-Very Good

Very Good

Fair-Good

Outstanding

Excellent

Excellent

Good

Excellent

Excellent

Poor

Good

Fair-Good

Good-Excellent

Outstanding

Excellent

Excellent

Good

Good

Excellent

Poor-

Good

Good

Good

Very Good

Outstanding

ELECTRICAL PROPERTIES

-

5.0-8.4 x 10^8

2.0 x 10^16

3.5 x 10^10

2.0 x 10^13

1 x 10^14

- 1 x

10^16

2 x 10^13

-

2 x 10^16 - 1 x 10^17

0.3 x 10^10 - 4.7 x 10^13

400-600

-

600-800

600-900

250

400-600

400-700

500

-

500-1000

330-700

THERMAL PROPERTIES

Service Tempera

-70

-

-65

-50

-65

-60

-178

-40

-50

-70

-65

250

-

225

300

250

225

600

550

275

350

200

B-C

-

B

A

B

B-A

A

A

B-A

B-A

B

ENVIRONME RESISTANCE

Poor

Poor

Excellent

Poor

Very Good

Excellent

Outstanding

Excellent

Outstanding

Excellent

Good

Good

Excellent

Fair-Good

Very Good

Excellent

Outstanding

Excellent

Excellent

Excellent

Fair

Fair Excellent

Good

Very Good

Good

Excellent

Excellent

Excellent

Outstanding

Good

Excellent

Excellent

Excellent

Excellent

Good

Excellent

Good

Good

Excellent

Good-Excellent

Fair-Good

Good

Poor

Fair-Good

Good

Fair-Good

Fair-Good

Poor

Good

Good-Excellent